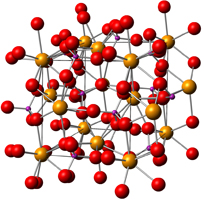

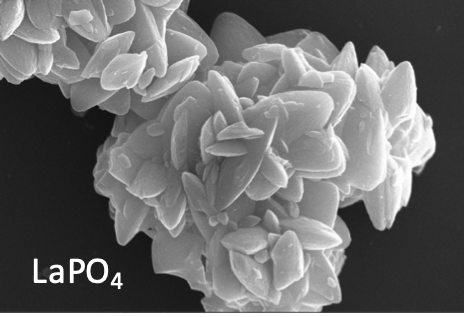

This unique material, monazite, can be synthesized at low temperatures using a direct precipitation method. Studies are on going on how best to process this material for proton conducting solid oxide fuel cells (SOFC) and light emitting diodes (LED).

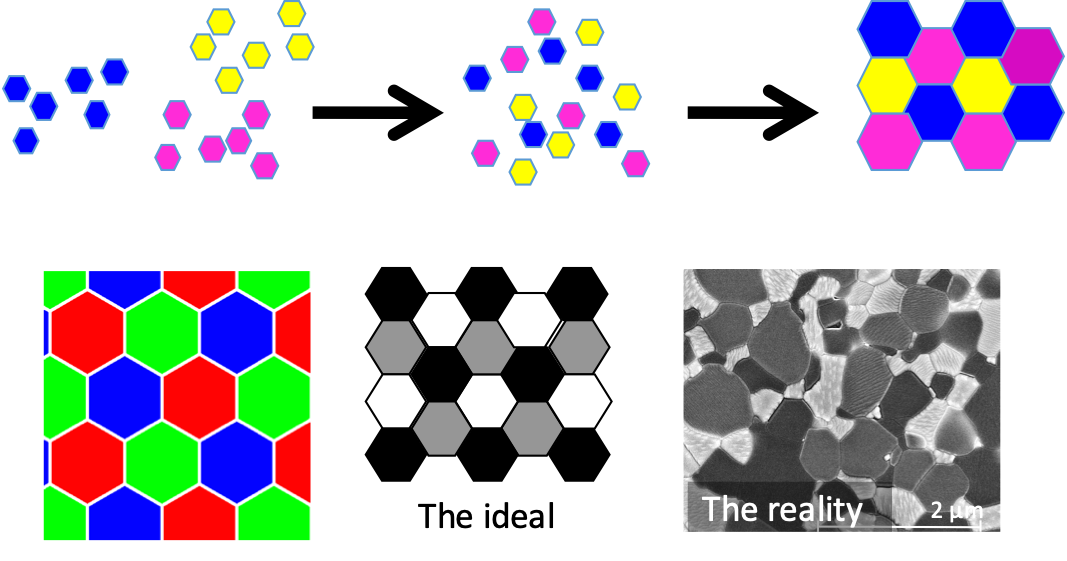

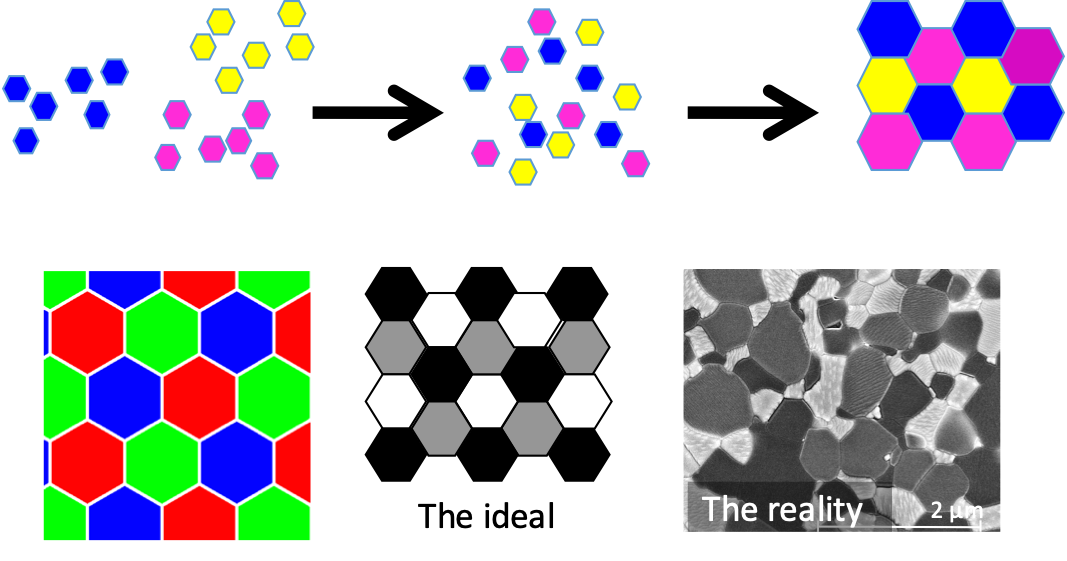

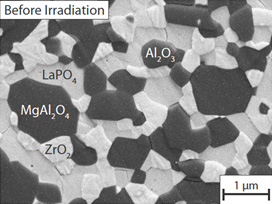

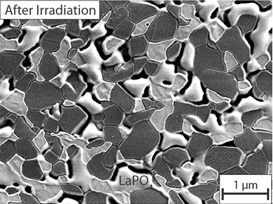

Multiphase ceramics used in nuclear fuel can improve thermal conductivity, accomodate fission products, and increase thermal shock and plasticity.

|

|

|

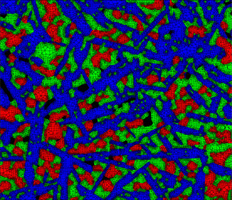

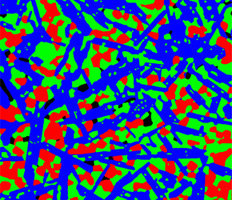

Through the use of computational modeling, the properties of multiphase ceramics can be predicted. Thermal, mechanical and electrical properties of different phases can be evaluated to understand how composition and microstructure affect bulk material behavior.

|

|

|

|

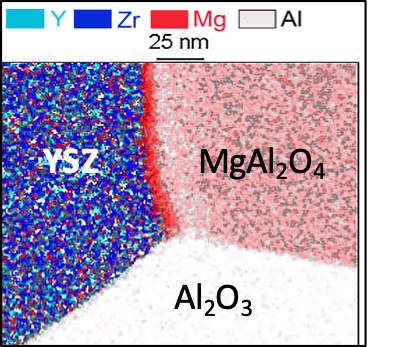

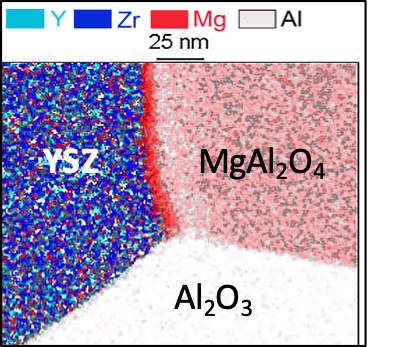

Zirconia based electrolytes show very poor thermal shock resistance to rapid temperature changes which can result in a total loss of mechanical strength. Applications such as SOFC and oxygen sensors can experience failure due to the low thermal shock stability of the electrolyte. Our studies show how the addition of second phases can improve thermal shock resistance

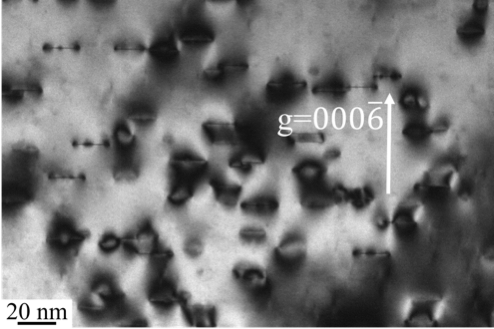

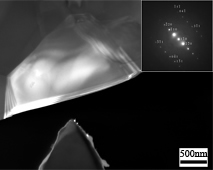

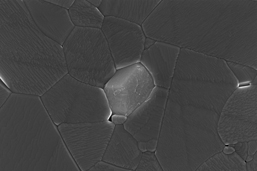

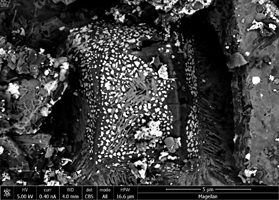

Electron microscopy is used to determine the basic deformation mechanisms including dislocation Burgers vectors and slip planes.

|

|

|

Experimental results indicate effective faster diffusion of oxygen in alumina exposed to water vapor at high temperatures.

|

|

Ceramic materials with the complex magnetoplumbite-type (M3+M2+MAl11O19) types crystal structure are synthesized for use as nuclear waste hosts and for catalytic combustion processes.

|

|

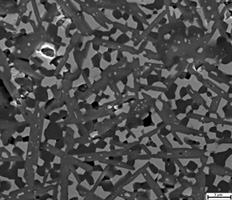

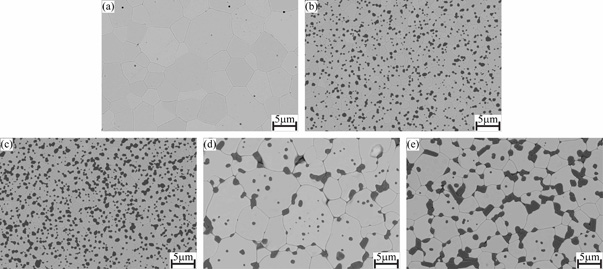

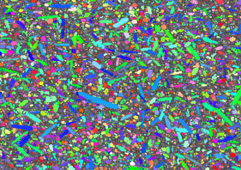

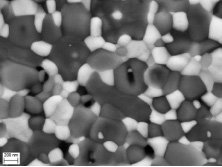

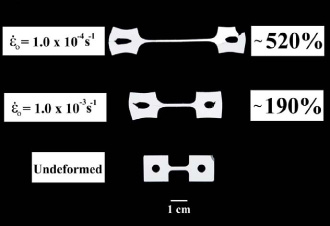

Multiphase fine grain microstructures allow superplastic net-shape forming at high temperatures yet still maintain high strength at room temperature.

|

|